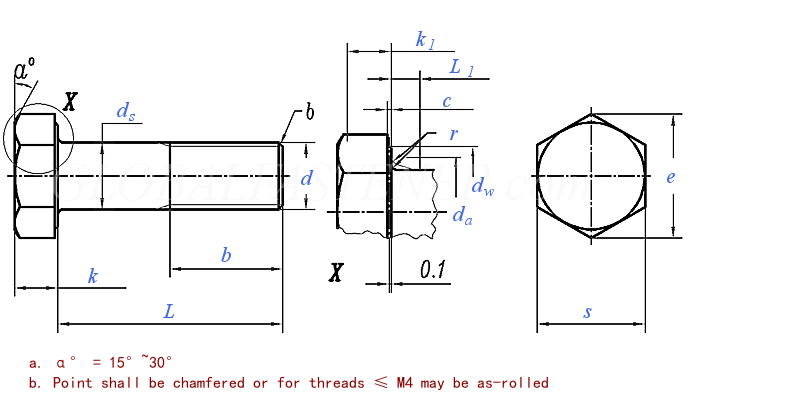

Tha boltaichean sia-thaobhach air an dèanamh a rèir DIN 931

| Ainm nan toraidhean | BOLT HEX DIN 931/ISO4014 leth-shnàthainn |

| Coitcheann | DIN, ASTM / ANSI JIS EN ISO, AS, GB |

| Ìre | Ìre stàilinn: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Crìochnachadh | Sinc (Buidhe, Geal, Gorm, Dubh), Hop Dip Galvanized (HDG), Black Oxide, Geomet, Dacroment, anodization, Nickel plated, Zinc-Nickel plated |

| Pròiseas Riochdachaidh | M2-M24: Fuar-bhrothaireachd, M24-M100 Teas-bhrothaireachd, Innealachadh agus CNC airson fastener gnàthaichte |

| Ùine luaidhe airson bathar gnàthaichte | 30-60 latha, |

| Snàthainn sgriubha | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Pàirce | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125 <L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | as àirde | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| mionaid | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | as àirde | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | meud ainmichte as motha = | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| Ìre A | mionaid | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| Ìre B | mionaid | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | Ìre A | mionaid | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Ìre B | mionaid | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Ìre A | mionaid | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Ìre B | mionaid | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | as àirde | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Meud Ainmeil | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Ìre A | as àirde | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| mionaid | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Ìre B | as àirde | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| mionaid | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Ìre A | mionaid | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Ìre B | mionaid | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | mionaid | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | meud ainmichte as motha = | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Ìre A | mionaid | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Ìre B | mionaid | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Fad an t-snàthainn b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Snàthainn sgriubha | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Pàirce | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125 <L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | as àirde | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| mionaid | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | as àirde | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | meud ainmichte as motha = | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| Ìre A | mionaid | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| Ìre B | mionaid | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | Ìre A | mionaid | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Ìre B | mionaid | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Ìre A | mionaid | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Ìre B | mionaid | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | as àirde | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Meud Ainmeil | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Ìre A | as àirde | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| mionaid | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Ìre B | as àirde | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| mionaid | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Ìre A | mionaid | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Ìre B | mionaid | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | mionaid | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | meud ainmichte as motha = | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Ìre A | mionaid | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Ìre B | mionaid | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Fad an t-snàthainn b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Snàthainn sgriubha | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | Pàirce | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125 <L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | as àirde | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| mionaid | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | as àirde | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | meud ainmichte as motha = | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| Ìre A | mionaid | - | - | - | - | - | - |

|

|

|

|

|

| |

| Ìre B | mionaid | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | Ìre A | mionaid | - | - | - | - | - | - |

|

|

|

|

|

|

| Ìre B | mionaid | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | Ìre A | mionaid | - | - | - | - | - | - |

|

|

|

|

|

|

| Ìre B | mionaid | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | as àirde | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Meud Ainmeil | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| Ìre A | as àirde | - | - | - | - | - | - |

|

|

|

|

|

| |

| mionaid | - | - | - | - | - | - |

|

|

|

|

|

| ||

| Ìre B | as àirde | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| mionaid | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | Ìre A | mionaid | - | - | - | - | - | - |

|

|

|

|

|

|

| Ìre B | mionaid | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | mionaid | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | meud ainmichte as motha = | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| Ìre A | mionaid | - | - | - | - | - | - |

|

|

|

|

|

| |

| Ìre B | mionaid | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Fad an t-snàthainn b | - | - | - | - | - | - |

|

|

|

|

| |||

Feartan agus Buannachdan

’S e seòrsa de cheangal a th’ ann am boltaichean heicsagonach a tha air a dhealbhadh le ceann sia-thaobhach agus seafta le snàthadh pàirteach. ’S e inbhe theicnigeach a th’ ann an DIN 931 a tha a’ mìneachadh nan riatanasan saothrachaidh airson boltaichean heicsagonach. Bithear a’ cleachdadh nam boltaichean seo gu cumanta ann an diofar thagraidhean gnìomhachais is meacanaigeach air sgàth an neart, an seasmhachd agus an iomadachd.

Is e aon de na prìomh fheartan de bholtaichean sia-cheàrnach a chaidh a chruthachadh a rèir DIN 931 an snàthadh pàirteach aca. Eu-coltach ri boltaichean làn-shnàthaichte, aig a bheil snàithleanan a ruitheas fad iomlan an t-shailean, chan eil snàithleanan aig boltaichean sia-cheàrnach ach air pàirt den fhaid aca. Leigidh an dealbhadh seo leis a’ bholt a bhith ceangailte gu tèarainte na àite agus aig an aon àm a’ toirt seachad àite gu leòr airson pàirtean gluasad nuair a bhios feum orra.

Is e taobh cudromach eile de bholtaichean sia-thaobhach an ceann sia-thaobhach aca. Tha grunn bhuannachdan aig an dealbhadh seo thairis air seòrsachan eile de bholtaichean. An toiseach, tha an cumadh sia-thaobhach a’ leigeil le teannachadh agus leigeil ma sgaoil nas fhasa le iuchair no socaid. San dàrna àite, tha farsaingeachd uachdar nas motha a’ chinn a’ sgaoileadh feachd an teannachaidh thairis air farsaingeachd nas fharsainge, a’ lughdachadh coltachd milleadh no deformachadh.

Tha boltaichean heicsagonach a chaidh a chruthachadh a rèir DIN 931 rim faighinn ann an raon farsaing de mheudan agus stuthan, gan dèanamh freagarrach airson raon farsaing de thagraidhean. Tha iad air an cleachdadh gu cumanta ann an innealan togail, chàraichean agus gnìomhachais, a bharrachd air ann am pròiseactan taighe agus DIY. Tha an neart, an seasmhachd agus an furasta an cleachdadh a’ dèanamh boltaichean heicsagonach nam pàirt riatanach ann an iomadh seòrsa inneal agus uidheamachd.

Mar gheàrr-chunntas, tha boltaichean sia-thaobhach a chaidh a chruthachadh a rèir DIN 931 air an dealbhadh gus fuasgladh ceangail tèarainte is earbsach a thoirt seachad airson grunn thagraidhean. Tha an cas le snàthadh pàirteach agus an ceann sia-thaobhach aca a’ tabhann grunn bhuannachdan, a’ gabhail a-steach furasta an cleachdadh, neart is seasmhachd nas motha, agus ioma-chruthachd. Tha na boltaichean seo nam pàirt riatanach de dh’ iomadh seòrsa inneal is uidheamachd, agus tha am mòr-chòrdte na fhianais air an càileachd agus an èifeachdas.