Àrd Neart Hex Bolt Din 933 / ISO4017 CL 8.8

| Ainm bathar | HEX BOLT DIN 931 / ISO4014 leth snàithlean |

| Inbhe | DIN, ASTM / ANSI JIS EN ISO, AS, GB |

| Ìre | Steel Ìre: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9;SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Crìochnaich | Sinc (Buidhe, Geal, Gorm, Dubh), Hop Dip Galvanized (HDG), Dubh Oxide, Geomet, Dacroment, anodization, Nickel plated, Sinc-Nickel plated |

| Pròiseas Riochdachaidh | M2-M24: losgann fuar, cruthachadh teth M24-M100, Machining agus CNC airson Customized fastener |

| Ùine stiùiridh toraidh gnàthaichte | 30-60 latha, |

| Snàthainn sgriubha | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

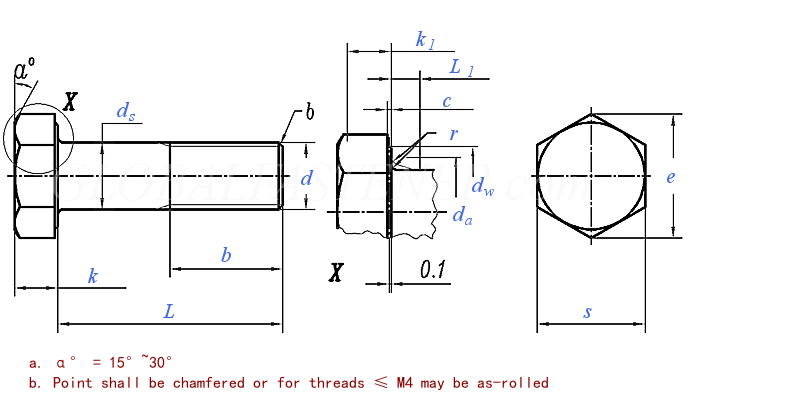

| P | Pairc | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | ≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L 200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | max = meud ainmichte | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| Ìre A | min | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| Ìre B | min | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | Ìre A | min | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Ìre B | min | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Ìre A | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Ìre B | min | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Meud Ainmeil | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Ìre A | max | 1.225 | 1.525 | 1.825 | 2. 125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| min | 0.975 | 1. 275 | 1. 575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Ìre B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| min | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Ìre A | min | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Ìre B | min | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | max = meud ainmichte | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Ìre A | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Ìre B | min | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Fad an t-Snàthainn b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Snàthainn sgriubha | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Pairc | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | ≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L 200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | max = meud ainmichte | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| Ìre A | min | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| Ìre B | min | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | Ìre A | min | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Ìre B | min | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Ìre A | min | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Ìre B | min | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Meud Ainmeil | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Ìre A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| min | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Ìre B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| min | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Ìre A | min | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Ìre B | min | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | max = meud ainmichte | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Ìre A | min | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Ìre B | min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Fad an t-Snàthainn b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Snàthainn sgriubha | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | Pairc | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | ≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125<L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L 200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| min | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | max = meud ainmichte | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| Ìre A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Ìre B | min | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | Ìre A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Ìre B | min | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | Ìre A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Ìre B | min | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Meud Ainmeil | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| Ìre A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| min | - | - | - | - | - | - |

|

|

|

|

|

| ||

| Ìre B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| min | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | Ìre A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Ìre B | min | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | min | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | max = meud ainmichte | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| Ìre A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Ìre B | min | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Fad an t-Snàthainn b | - | - | - | - | - | - |

|

|

|

|

| |||

Feartan agus buannachdan

Tha an Hex Bolt Din 933 / ISO4017 CL 8.8 Àrd-neart na fhuasgladh ceangail air leth làidir agus earbsach.Air a dhèanamh a rèir ìrean gnìomhachais as àirde, tha am bolt seo air a thogail le bhith a’ cleachdadh stuthan àrd-inbhe a nì cinnteach gum bi seasmhachd nas fheàrr agus an aghaidh caitheamh is deòir.Air a dhealbhadh le ceann hexagon, tha am bolt seo a ’comasachadh stàladh agus toirt air falbh gu furasta, ga dhèanamh na dheagh roghainn airson grunn thagraidhean gnìomhachais agus meacanaigeach.

Is e aon de phrìomh fheartan an toraidh seo an neart tensile àrd aige, a leigeas leis seasamh ri eadhon na h-uallaichean is cuideaman as cruaidhe.Co-dhiù a tha thu ag obair ann an gnìomhachasan togail, càraichean no innealan trom, tha am bolt seo gu cinnteach a’ toirt dhut an neart agus an taic riatanach gus an obair a dhèanamh.Leis an togail làidir agus an crìochnachadh impeccable aige, tha am bolt seo air a thogail gus mairsinn, a’ dèanamh cinnteach à coileanadh maireannach agus earbsachd.

A’ cumail ri inbhean DIN 933 agus ISO4017, tha am bolt hex seo a’ coinneachadh ri riatanasan agus sònrachadh sònraichte a’ ghnìomhachais, ga fhàgail na roghainn as fheàrr le proifeiseantaich tuigseach.Leis an innealachadh mionaideach agus na ceumannan smachd càileachd teann, tha am bolt seo air a dhealbhadh gus an sàbhailteachd agus an earbsa as motha a thabhann anns a h-uile tagradh.

Ri fhaighinn ann an diofar mheudan agus shònrachaidhean, tha an Hex Bolt Din 933 / ISO4017 CL 8.8 Àrd-neart seo freagarrach airson raon farsaing de thagraidhean agus ghnìomhachasan.Co-dhiù a tha thu a ’coimhead airson fuasgladh ceangail airson obair stàilinn structarail, innealan trom, no stàladh uidheamachd, tha am bolt seo gu cinnteach a’ toirt dhut an neart agus an seasmhachd riatanach airson na h-obrach.

Gu crìch, ma tha thu a’ coimhead airson fuasgladh luathachaidh earbsach, àrd-neart a sheasas na h-uallaichean agus na cuideaman as cruaidhe, is e an High Strength Hex Bolt Din 933 / ISO4017 CL 8.8 an roghainn foirfe dhut.Leis an innealachadh mionaideach aige, ceumannan smachd càileachd teann, agus gèilleadh ri inbhean gnìomhachais, tha am bolt seo gu cinnteach a ’toirt dhut an sàbhailteachd agus an earbsachd riatanach a dh’ fheumas tu gus an obair a dhèanamh ceart.